In-house Decoration

Adding your logo to a product can be more than just printing

and can be an opportunity to demonstrate creativity. Here are some of the options we can provide…

We don’t do ‘logo-slapping’, we work with our customers to determine the most applicable way to brand products to ensure that they get the exposure that they desire but that the size, position and reproduction of the brand icon doesn’t impede the use and enjoyment of the product. Often the best exposure comes from more subtle or even tonal branding rather than the outdated philosophy that big is best!

Accurate and representative decoration of products is critical for a successful campaign and a satisfied customer. Whilst decoration techniques continue to evolve with innovative new technology based techniques, we remain invested in the process.

Here are some examples of the different branding techniques that we use to help recreate our customers logos and campaign messages accurately, attractively and in a way that enhances the product and doesn’t discourage the recipient from using.

Screen printing

Embroidery & appliqué

Embroidery is still considered the most prestigious and hardwearing method of branding textiles and is often chosen for formal shirts, uniforms and luggage. Embroidery involves recreating an artwork file using tiny stitches and coloured thread. The result is vibrant and durable but doesn’t have the same level of accuracy as printing techniques.

Whilst modern digital embroidery enables the most accurate stitching ever, there are variables which will impact the price and accuracy of this technique. How detailed your artwork is, the type of colours and the fabric it’s being applied to all affect the final results. Appliqué is a relatively new process that involves embroidering separate badges or backing fabrics which can enhance the accuracy too.

Other new trending techniques also involve using layered, raised stitches to create a tactile 3D affect or embroidering highlighted areas over pre-printed graphics to create a sophisticated multi-layered result.

At our facility in Hayes we have an expert team of embroidery professionals who operate a range of impressive large scale embroidery machines that interpret digital files and duplicate embroidery en masse – stitching 1000s of stitches every minute onto simultaneous garments.

A typical process involves:

• Firstly, your custom design or logo will be loaded into software that maps the required colours and patterns to create a digital stitch file.

• The embroiderer will then apply a circular frame called a vilene around the area to be embroidered, this keeps the surface of the textile taut, smooth and flat.

• Once the garment is in place beneath the needle the sewing process begins, sewing one colour element at a time, between 10 and 14 colours a time if required.

Once the stitching is complete, the vilene is removed and any excess thread is trimmed and the item Is ready to use.

Laser Engraving

Due the nature of the materials suited to this technique, engraving items is often seen as a premium method of decoration or personalisation.

A digital evolution of hand engraving, commonly used on jewellery and watches, laser engraving enables fast, large scale duplicate engravings that use digital precision for detailed, consistent reproductions, and variable depths and shapes of etches to create incredibly detailed affects.

The ‘carving’ of the surface doesn’t allow for colour reproduction, but does leave a tactile finish that can be felt as ‘raised’ from the surface. Favoured on metal items like pens, luggage tags and technology devices, some innovations include engraving a surface and adding LEDs to illuminate the carve outline / silhouette from behind.

A typical process involves:

• The process begins with a hi res artwork file. Our team then simplifies the artwork to create a single colour outline, as engraving cannot reproduce complex 4 colour / digital process.

• Specialist software creates a map guide for the laser, which will be used to remove the surface of material revealing the colour or texture beneath to create the design.

Engraving is the most permanent form of branding on any product.

There are so many ways that we can decorate products to optimise the impact of your brand - here are some more examples.

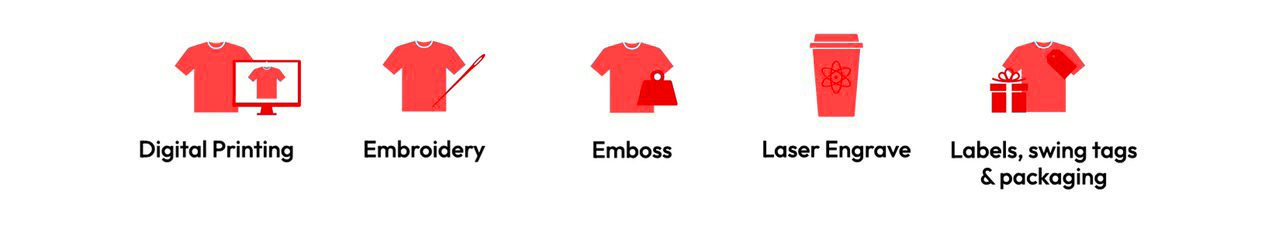

Sublimation Print

Screen Transfer

Digital Print

Digital Transfer